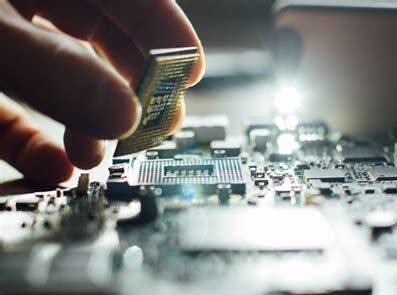

SCREENING DEVICES/COMPONENTS

-Manages QCI and NRE’s (tooling, programming, burn in boards) date code approvals

-Supply Chain : Raw Components purchased through approved Franchised Distributors and approved manufacturers.

-Functional Testing -Verify that the component performs its intended function - Testing electrical components for correct voltage, current, and resistance. -Checking mechanical parts for proper motion or load-bearing capacity

-Environmental Stress Screening (ESS) -Thermal Cycling -Vibration Testing -Humidity Testing

-Electrical Testing - Ensure electrical components meet design specifications. - Parameters Tested - X-Ray and Imaging

-Burn-In Testing -Operate components at maximum stress levels for an extended period to detect early-life failures.

-Chemical and Material Testing -Verify the material composition and resistance to chemicals or environmental conditions. -Corrosion testing, material analysis, and chemical exposure testing

-Provide best pricing and Lead-Time

-Screened to Customer Drawings and Requirements

Recent Comments